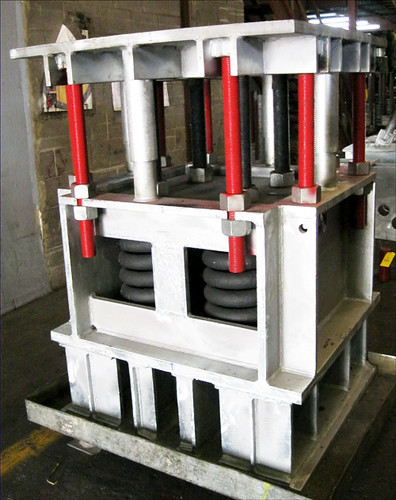

These hydraulic snubber assemblies were designed with maximum load capacities ranging from 1700 lb. to 59,400 lb. All of the snubbers were provided with an overall stroke of 6” and were preset to the midpoint of the total stroke, meaning that during operation, these snubbers could accommodate piping deflections of +/- 3” from the installed position.

The piston diameters range from 1-1/2″ to 6″ and the total assembly length ranges from 31-1/2″ to 220″. The largest assembly required a custom extension section to eliminate the risk of buckling under compression loads. Two-thirds of the assemblies included dual end brackets and the remaining assemblies included an end bracket/clamp combination. The housing, extension piece and end brackets are fabricated from carbon steel, while the cylinders, pins and two of the end brackets are fabricated from polished stainless steel. Standard “lock and bleed-down” tests were performed prior to shipping to a LNG processing facility in Peru.

Do you require a shock control device in your piping system? Price a snubber today!

Read More