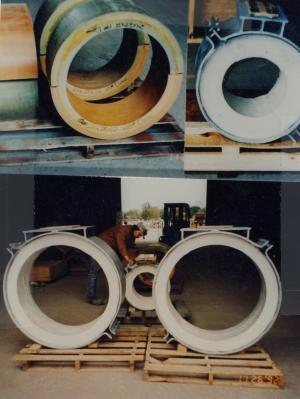

The pictures above show pipe supports designed for a system with very cold operating temperatures. The insulating components are polyurethane, which are inside the galvanized steel exterior of the support. At the top left of the picture are the color-coded polyurethane components of a “cold shoe” for a 60” pipe, the top (green) is 14 lb/ft3 density and the bottom (orange) is 20 lb/ft3 density. The higher density material has greater compressive strength but it is a better conductor of heat. The other pictures show finished shoes which have white coating over the polyurethane. Hot shoes, designed for high operating temperatures, are similar but usually have different insulating materials.

Want to learn more about pre-insulated supports? View a recording of a past live pre-insulated webinar.